DLE that meets real-world demands

-

Efficiency drives 20% lower capex intensity*

-

50% lower DLE fresh water use*

-

Engineered for brines between 50-3000mg/L lithium

-

Derisks scale up with a practical, stage-gated approach

*compared to commercial DLE benchmarks

Field-proven performance and reliability

Summit successfully operated a denaLi™ DLE pilot plant at Albemarle’s site in Northern Chile in 2025. The fully integrated system followed a commercial‑scale flowsheet and demonstrated sorbent performance over a pre-defined 20‑week period, supported by reliable automation and control systems.

.png?width=1920&height=1080&name=Untitled%20design%20(1).png)

A faster, clearer path to commercial validation

Summit has commenced operations at our new in-house demonstration plant in Santiago, giving developers a commercially grounded validation pathway long before full-scale deployment. This accelerated approach helps eliminate uncertainty, sharpen project economics, and ensure that capital is directed toward technologies capable of delivering at industrial scale.

Rapid, integrated evaluation workflow

Early visibility into scale‑up risks

Decision-grade data for engineering & economics

.jpg?width=2000&height=1333&name=DSC03938%20(1).jpg)

Evidence you can build on

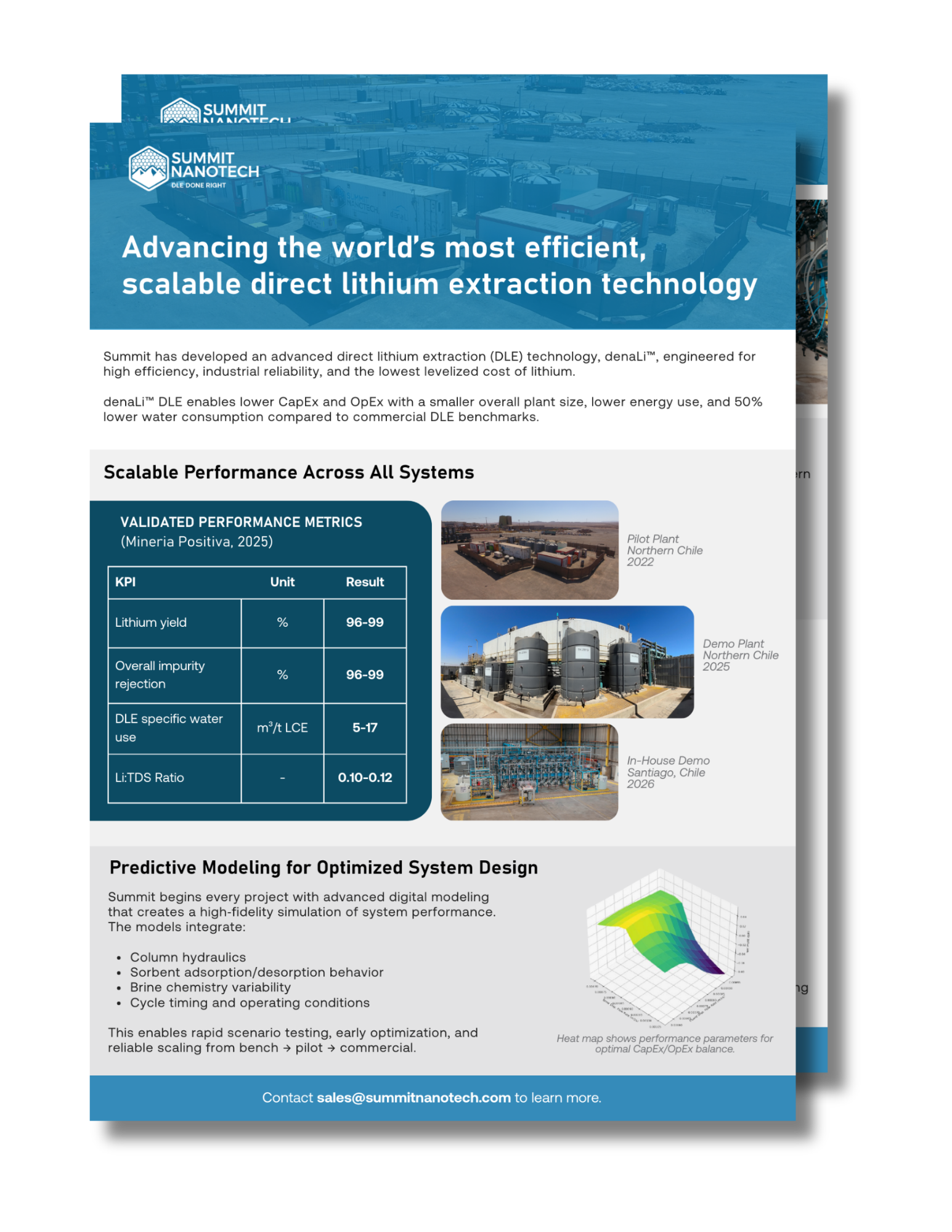

Our new performance one‑pager brings together results from internal and third-party testing programs to help developers quickly assess denaLi™ DLE technology fit and potential.

Download it to see representative performance ranges, insights about our approach, and the indicators most relevant to project economics.

Frequently asked questions

-

What does Summit do?

Summit develops advanced direct lithium extraction (DLE) technology that enables producers to extract lithium from brine more efficiently. Our denaLi™ system and eLivate™ sorbent deliver high recovery, the lowest water use, and the lowest levelized cost of lithium. The technology is designed for industrial scalability and has been validated in real-world conditions at Albemarle’s site in Northern Chile.

-

How does Summit differ from other DLE solutions?

Summit achieves the DLE trifecta: high lithium recovery, high impurity rejection, and ultra-low water use. Our system uses a patent-pending flow sequencing method that optimizes water efficiency without increasing energy requirements. Unlike other approaches that often require additional evaporators or crystallizers downstream, Summit’s design minimizes complexity and cost. Our multi-column system is engineered for scalability and reliability, and our proprietary sorbent offers superior capacity and kinetics compared to competitors.

-

Where does Summit operate?

Summit is active in Chile, Argentina, and the United States. These regions were selected for their economic viability, geopolitical stability, and advanced development stage. We maintain offices in Calgary, Denver, Santiago, and Salta to support local operations and partnerships.

-

What is denaLi™ DLE?

denaLi™ is a modular multi-column DLE system designed to integrate seamlessly with existing brine processing infrastructure. It uses multiple columns to optimize lithium recovery and minimize water use. The system is engineered for flexibility, allowing customization for different brine chemistries and operational requirements.

-

What is eLivate™ sorbent?

eLivate™ is Summit’s proprietary sorbent, designed for industrial-grade durability and efficiency. It combines high capacity, fast kinetics, and strong selectivity to maximize lithium recovery while reducing energy and water use. The sorbent has an estimated lifespan of 5–8 years, zero mechanical attrition in extended testing, and robust chemical stability across a wide range of brine chemistries. It is regenerable, which further reduces lifecycle costs.

-

How does Summit address environmental concerns?

Our technology reduces total water footprint by up to 50 percent compared to commercial DLE benchmarks and 30 percent compared to evaporation ponds. We achieve these results without increasing energy consumption, ensuring sustainability and cost efficiency go hand in hand.

-

What is Summit's timeline for commercialization?

Summit has proven its technology at demonstration scale and completed initial engineering design for a 25,000 tonne per year plant. We are ready to deliver projects above 5,000 tonnes per year using modular systems. Our focus is on scaling reliably and delivering consistent, market-leading performance with the lowest levelized cost of lithium.

.png?width=300&height=95&name=Color%20Logo%20-%20DLE%20Done%20Right%20(2).png)

.png?width=411&height=150&name=PDAC_2026_logo_RGB_hor_website-med%20(1).png)